PhotonDelta investment in chip-scale chemical monitoring is signaling a quiet but meaningful shift in how industries may track chemistry in real time. Raman spectroscopy has long been praised for its atomic-level accuracy, yet its dependence on bulky laboratory equipment has kept it locked away from factory floors, pipelines, and portable environments. Despite its Nobel Prize roots dating back to 1930, the technology has struggled to escape controlled lab settings. That limitation has become more painful as modern biomanufacturing, pharmaceuticals, and advanced materials demand constant chemical insight rather than periodic lab tests.

This gap is what Perceptra set out to close. Born as a spin-off from research at MIT, the company is working to compress decades-old Raman spectroscopy hardware into a silicon-based photonic chip. Instead of relying on large dispersive spectrometers and complex optical benches, Perceptra uses tunable on-chip lasers, integrated detectors, and machine learning models that interpret faint optical signals with speed and precision. The outcome is a handheld system that performs chemical identification at a fraction of the size and cost of traditional setups.

That vision has now attracted fresh backing. Perceptra has secured €1.2 million from PhotonDelta, Europe’s leading photonics accelerator. The funding is structured as a loan and will support the company’s next technical milestone. With this capital, the startup plans to complete its first fully photonic Raman sensor and move its research and development operations from San Francisco to the Netherlands, placing it closer to advanced photonic manufacturing infrastructure.

At the heart of Perceptra’s approach is the idea that chemical sensing should be as effortless as reading a digital thermometer. Amir Atabaki, the company’s CEO and co-founder, spent years inside MIT photonics labs working on how light behaves when confined to silicon. During that time, he noticed a sharp contrast. Computing had shrunk from room-sized machines into pocket devices, yet Raman spectroscopy remained stuck in a bulky, analog past. Meanwhile, industries worth trillions of euros were calling for continuous, automated chemical monitoring that could run around the clock.

Perceptra’s technology replaces benchtop optics with photonic integrated circuits. These PICs are manufactured using processes similar to those used in semiconductor fabs, which drastically lowers cost and improves scalability. By integrating tunable lasers, waveguides, and detectors onto a single silicon chip, the system eliminates many of the alignment challenges that make traditional Raman instruments expensive and fragile. This integration also allows the sensor to operate in harsher industrial environments where vibration, dust, and temperature swings are unavoidable.

A major challenge in chip-scale Raman sensing is signal quality. Raman scattering is inherently weak, and shrinking detectors can make the signal harder to read. Perceptra addresses this with AI-driven signal extraction models that enhance meaningful spectral data while filtering noise. Because the detectors themselves are simpler and roughly ten times cheaper than conventional components, the overall system cost drops without sacrificing accuracy. The result is a compact sensor capable of delivering laboratory-grade insights outside the lab.

This approach sets Perceptra apart from established players. Traditional spectroscopy vendors such as Wasatch Photonics, Metrohm, and B&W Tek have made progress in miniaturization, but their systems still rely on discrete optical components and conventional architectures. Perceptra’s decision to integrate nearly everything onto silicon represents a deeper redesign rather than an incremental improvement. It is closer to what system-on-chip design did for computing hardware decades ago.

PhotonDelta’s involvement adds strategic weight to this effort. The Dutch ecosystem has invested heavily in photonics as a foundational technology, building a dense network of fabs, suppliers, and specialized talent. By relocating its R&D base to the Netherlands, Perceptra gains access to manufacturing partners capable of producing advanced PICs at scale. This move also shortens the path from prototype to pilot production, a critical factor for hardware startups aiming to enter regulated industrial markets.

The immediate focus for the company is commercialization. The new funding will support the development of Perceptra’s first market-ready Raman sensor, designed for early pilots in biomanufacturing. In these environments, real-time chemical monitoring can detect process drift, contamination, or yield losses before they become costly failures. Continuous sensing could replace manual sampling routines, reduce downtime, and improve product consistency across batches.

Beyond biomanufacturing, the implications are broader. Compact Raman sensors could be deployed in environmental monitoring, food safety, and advanced materials processing. Because the system is designed to be portable, it opens possibilities for field use where sending samples to a lab is slow or impractical. Over time, the company envisions its technology becoming an invisible layer of chemical awareness embedded into industrial systems.

The decision to structure the €1.2 million funding as a loan also reflects confidence in near-term revenue potential. PhotonDelta’s model often emphasizes helping startups reach commercial inflection points rather than relying solely on equity dilution. For Perceptra, this means the pressure is on to deliver working sensors that can prove value in real-world conditions. Early pilot success will likely determine how quickly the company can scale manufacturing and expand into additional markets.

Perceptra’s journey illustrates how old scientific breakthroughs can gain new life when paired with modern engineering. Raman spectroscopy has always offered powerful insights, but its form factor limited its reach. By translating optical physics into silicon and augmenting it with AI, the company is betting that chemical sensing can finally follow the same miniaturization curve that transformed computing, imaging, and communications.

If successful, this shift could redefine expectations across multiple industries. Instead of episodic lab tests, companies may come to expect constant chemical visibility as a standard operational feature. PhotonDelta’s backing suggests that Europe’s photonics ecosystem sees this as more than a niche application. It views chip-scale chemical monitoring as a foundational capability with long-term economic and strategic value.

Five SEO-optimized titles include: PhotonDelta investment sparks major shift in chip-scale chemical monitoring. PhotonDelta backing signals critical leap for portable Raman sensing. PhotonDelta funding drives surprising progress in silicon-based chemical analysis. PhotonDelta loan marks essential milestone for photonic Raman chips. PhotonDelta support accelerates bold rethink of chemical monitoring.

Five meta descriptions include: Discover how PhotonDelta investment is transforming chip-scale chemical monitoring with photonic Raman sensors. Learn why PhotonDelta backing could reshape portable chemical analysis across industries. Explore the major impact of PhotonDelta funding on silicon-based Raman spectroscopy. See how PhotonDelta support is accelerating real-time chemical monitoring innovation. Find out why PhotonDelta’s move matters for the future of photonic sensing.

SEO-optimized image alt text suggestions include: PhotonDelta-backed photonic chip for chemical monitoring, Silicon photonic Raman sensor for real-time analysis, Chip-scale chemical monitoring device supported by PhotonDelta, Integrated photonic circuit for Raman spectroscopy, Portable chemical monitoring sensor using silicon photonics.

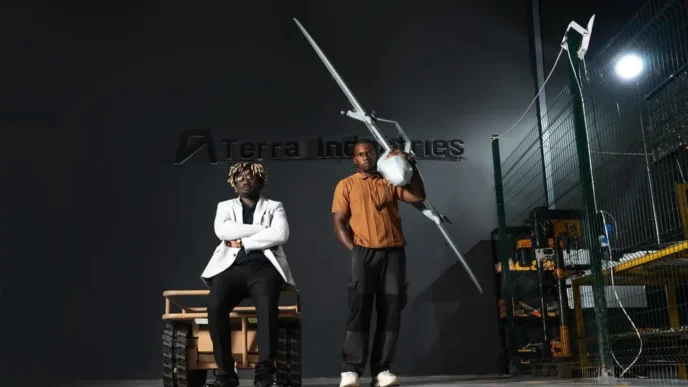

Three relevant internal link suggestions include: an explainer on silicon photonics manufacturing, a feature on European deep-tech accelerators, and an analysis of AI in industrial sensing. Two high-authority external link suggestions include MIT photonics research publications and European photonics industry reports. Image type suggestions suitable for the article include photonic chip close-ups, laboratory prototype photography, silicon wafer fabrication visuals, and industrial biomanufacturing process images.